Hepworth Clay pipes and fittings can be used for the majority of drainage installations. Whether it’s domestic, adoptable, commercial or industrial drainage you are installing.

Clay’s main benefits are its durability and longevity, plus it has a good environmental profile from a raw material through manufacturing, installation, in-use to end of life. The ultimate sustainable, durable, cost-efficient and high-performance sewerage solution.

Why Hepworth Clay pipe?

![]()

![]()

Superior Sustainability

Clay is a future-proof material, 100% natural and 100% recyclable.

Superior Quality

Hepworth SuperSleve products are kitemarked to BS EN 295-1, have a CE mark and Declaration of Performance (DoP), and are manufactured under a quality system approved to BS EN ISO 9001.

Superior Strength and Durability

Naturally high product strength enhances in-use performance resulting in a lifetime expectancy of over 100 years.

Superior Sustainability

Clay is a future-proof material, 100% natural and 100% recyclable.

![]()

Superior Quality

Hepworth SuperSleve products are kitemarked to BS EN 295-1, have a CE mark and Declaration of Performance (DoP), and are manufactured under a quality system approved to BS EN ISO 9001.

![]()

Superior Strength and Durability

Naturally high product strength enhances in-use performance resulting in a lifetime expectancy of over 100 years.

![]()

![]()

![]()

![]()

Superior Jetting Performance

Hepworth Clay SuperSleve pipe has a Lifetime Jetting Guarantee* 7500 psi at a flow rate not exceeding 20 gals/min held static for 5 minutes, providing a 50% higher operating pressure than the WRc requirement for clay pipes.

![]()

Superior chemical resistance

Clay is the perfect choice for contaminated brownfield sites as it is unaffected by effluent allowed in an adopted sewer system.

![]()

Superior bedding performance

We can advise on the use of recycled aggregate as bedding material for clay drainage reducing costs and environmental impact.

Superior Jetting Performance

Hepworth Clay SuperSleve pipe has a Lifetime Jetting Guarantee* 7500 psi at a flow rate not exceeding 20 gals/min held static for 5 minutes, providing a 50% higher operating pressure than the WRc requirement for clay pipes.

Superior chemical resistance

Clay is the perfect choice for contaminated brownfield sites as it is unaffected by effluent allowed in an adopted sewer system.

Superior bedding performance

We can advise on the use of recycled aggregate as bedding material for clay drainage reducing costs and environmental impact.

The Hepworth Clay Range

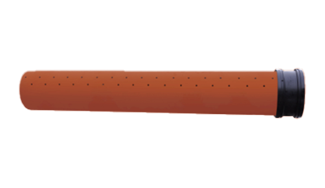

Hepworth Clay drainage system comprises a range of perforated and non-perforated vitrified clay pipes supplied complete with factory-fitted push-fit flexible couplings or plain ended with separate couplings to be fitted on site. Nitrile fittings for installation in previously contaminated ground.

Bends, junctions and fittings are available in 100mm, 150mm, 225mm and 300mm diameters. Channels, gullies and Inspection Chambers available in a range of sizes.

SuperSleve 100-300mm

clay pipes, fittings & gullies

For use in housing, adoptable,

commercial, industrial, and road drainage

For adoptable and non-adoptable applications

Hepworth Clay Product Guide

Download our full Hepworth Clay Product, Design and Installation guide.

How to videos

This brief overview of Hepworth Clay drainage, from raw material to finished product, highlights how its superior sustainability benefits the built environment.

This video will show you how to join Hepworth Clay pipes using couplings and lubricant for best results.

This video will show you how to join Hepworth Clay pipes using couplings and lubricant for best results.

See how to air test clay pipes

This video shows some methods to troubleshoot clay pipe air test failures

How to dismantle a Hepworth Clay pipe pack.